Hydraulic Systems For

Industrial

Central Hydraulic Power Unit

Central HPU drives many functions in a Food Processing Facility including:

- conveyors

- palletizers

- press equipment

Hydraulic accumulator aids in peak flow situation.

Kidney loop provides cooling and filtration of oil at all times.

Specifications

Florida Polytechnic Movable Louvers

Skanska USA

Lakeland, FL

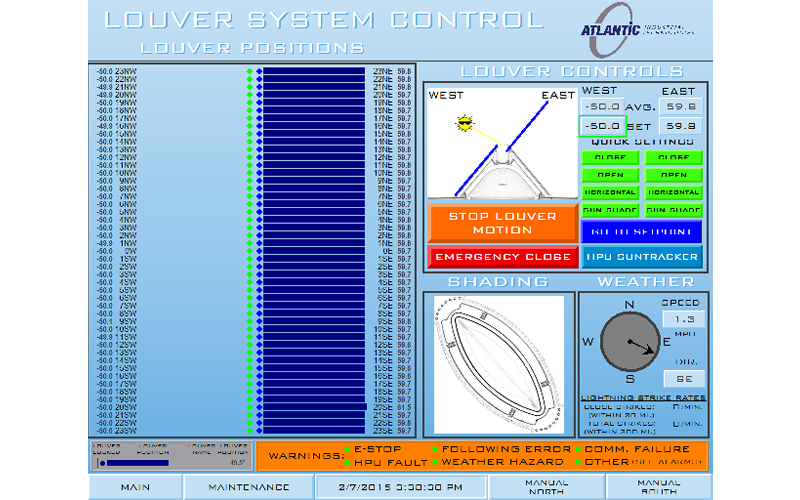

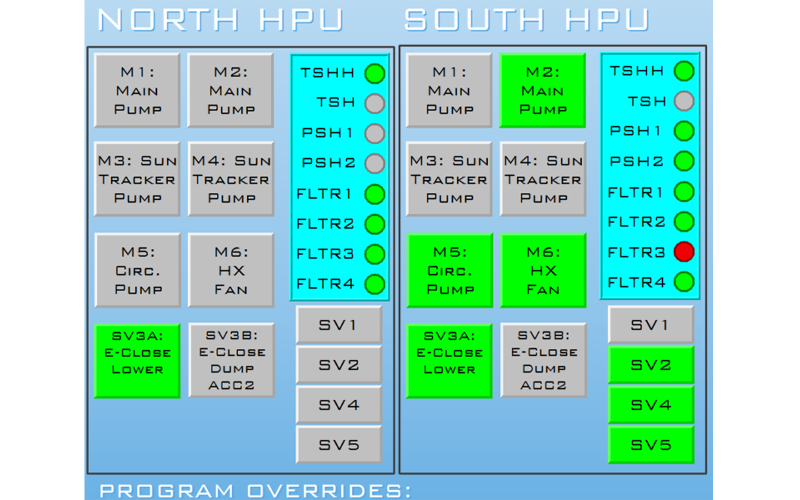

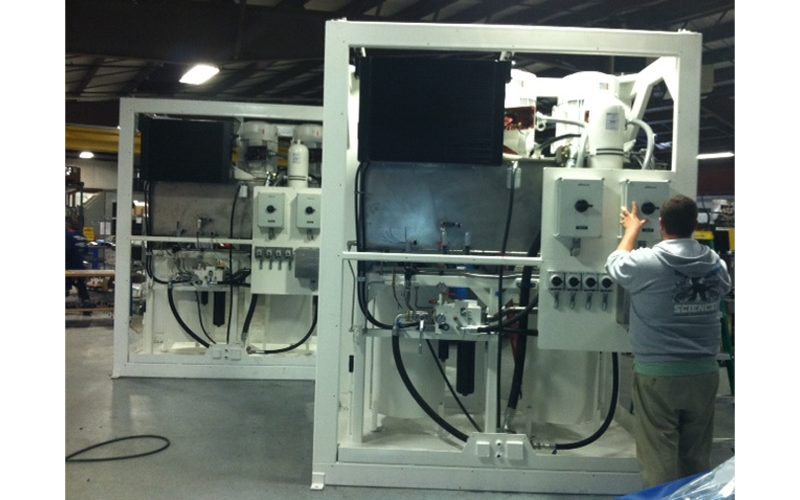

Atlantic Hydraulic Systems was tasked by Skanska USA and MG McGrath Corp to design, Manufacture and Commission a 94 axis hydraulic servo system to maneuver the roof louvers for the new Iconic student center at Florida Polytechnic University.

Features Include:

- Individual louver control

- Automatic retraction due to high winds or lightening

- Locking mechanisms for each louver in down position

- Graphic touchscreens depicting each louver position and locking status

Specifications

500 Ton Hydraulic Filter Press

Specifications

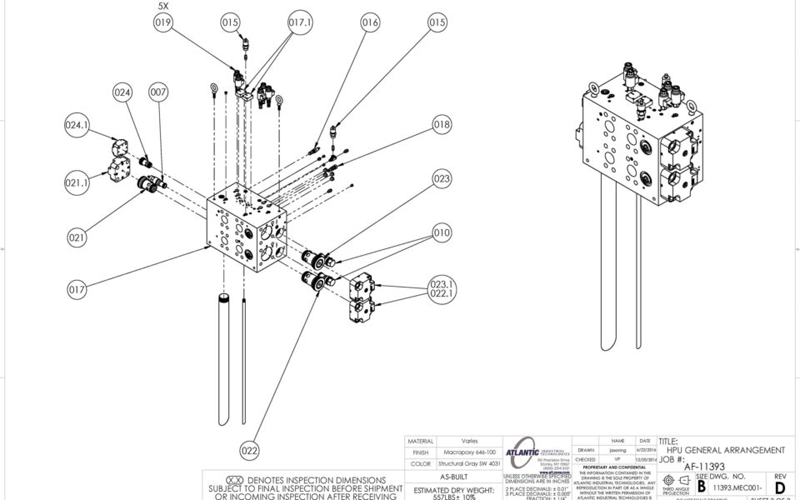

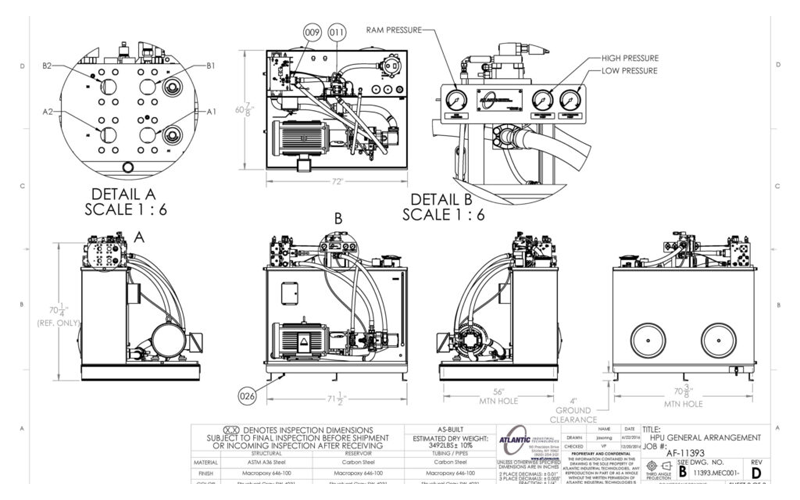

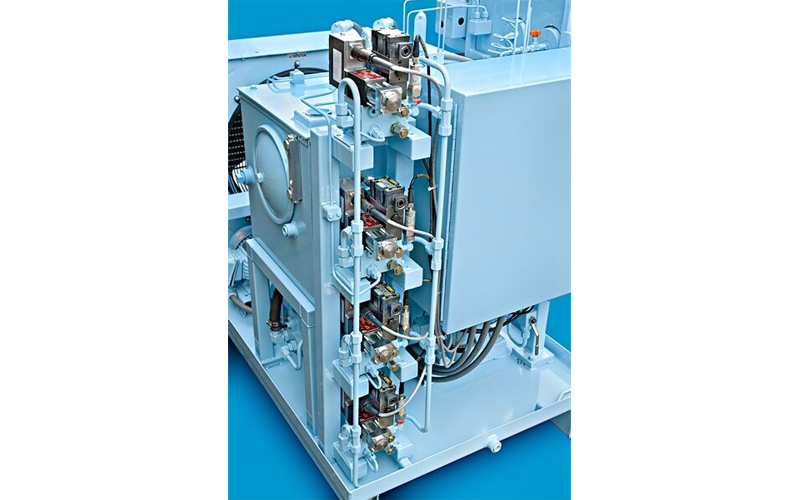

Aerospace Dynamic Testing Hydraulic Power Unit

Pratt & Whitney

Hartford, CT

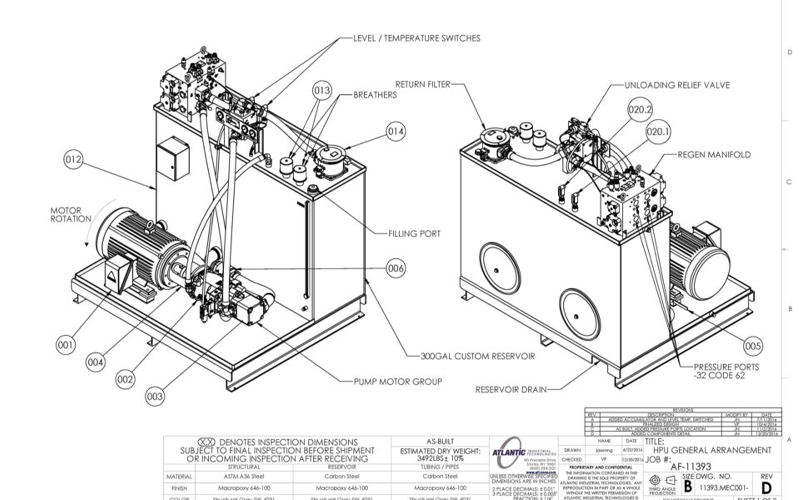

Engine manufacturer Pratt & Whitney commissioned Atlantic Hydraulic Systems to design and manufacture this hydraulic power unit for developmental testing of their new engine series.

Development tests take several years throughout the entire engine development program and consume a significant part of the total development costs. All of this is necessary to prove the engine meets all the operational and safety requirements.

The system utilizes (5) servo valve axes to apply random forces to the engine’s cowling during the testing phase.

Specifications

Stay Up To Date With Latest Blogs

Air in your Hydraulic Oil?

How do I prevent air from getting in to my hydraulic oil? Does it sound like there are marbles in your hydraulic pump?

Raising the Roof in Lakeland Florida

Fun engineering has always been a staple at Atlantic Industrial Technologies. We were honored to be selected to design, manufacture, install, and commission..

5 Best way to Design a Hydraulic

System that runs cool

Very simply… the best way to have a cool running hydraulic system is to design it to draw the least amount energy as..